The inefficient and expensive Compressed Air is used in every manufacturing industry worldwide.

To a large extent, the can manufacturing industry consumes compressed air, for example in the bodymaker and the cupper. Compressed air is used there as so-called strip air.

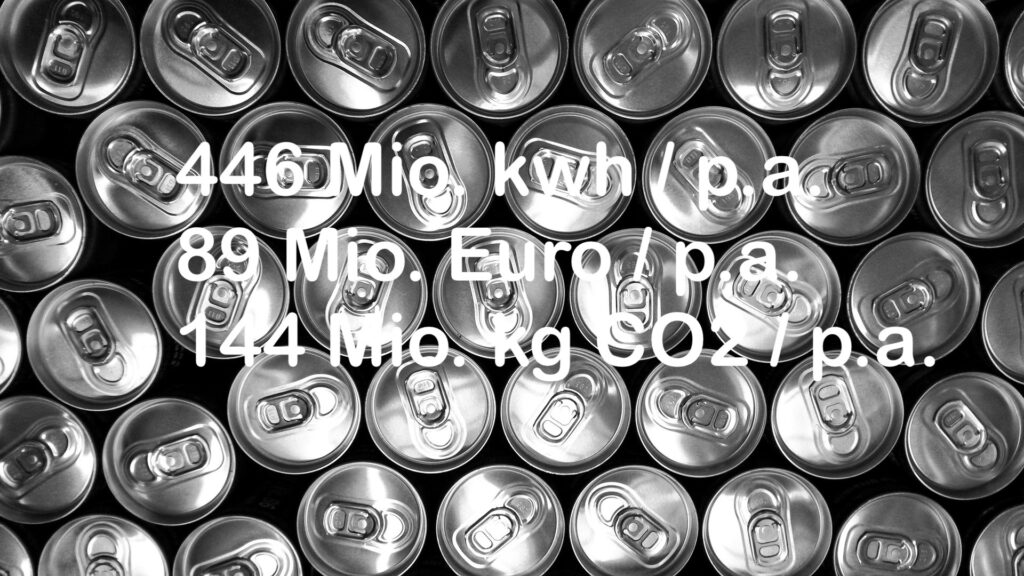

There are about 350 plants worldwide. In these plants, cans are produced on approx. 5,600 Bodymakers and approx. 700 Cuppers. The compressed air consumes millions of dollars in energy costs. The can industry, always criticized for sustainability, has found a solution with the AirFlowSaver from KTW Technologie to save compressed air and thus energy.

Per Bodymaker this is 22,600 kwh per year and in the Cupper even 456,000 kwh.

With this, the industry sets an exclamation mark to save more than 100 million kg CO2 per year and this with an investment ROI of less than 3 months.