A. Market and Consumer

A.1 Fast changing market trends and consumer behaviors

Online retail and the rapidly growing delivery services in cities have changed consumer behavior. The young generation of digital natives in particular is focusing on individuality!

The consumer selects his goods individually using digital media. He does not have to go to a store or observe any opening hours. The Internet is open day and night.

In addition to the endless choices offered by online marketplaces and delivery services, consumers want personalized products that are made specifically for them. They are also willing to spend more money for this.

A.2 Individualization has arrived in the beverage industry!

The market’s drive for more individualization has also reached the beverage industry. New beverage concepts are springing up every day. The range of beverages is growing almost endlessly. In particular, the trends toward more wellness, health, and life style seem to be especially attractive.

A.3 The optimal level of customization is not available

But the current offer of customisation is limited to a predefined and limited selection of beverages that do not fully meet the consumer’s wishes. Efforts to perfect customisation currently end in solutions that consumers mix themselves, for example by adding powders or concentrates such as syrup.

An optimal homogenisation of a beverage to serve a high quality product is not achieved by this. Especially for high-quality beverage solutions, a machine filling solution is needed.

A.4 Increasing market trend to functional, sporty and healthy drinks

Functional beverages are those that include desirable ingredients that have a positive impact on health or performance. This can include drinks with added nutrients, sports and energy drinks, meal replacements, and more.

The goal of a functional beverage is to target a specific function of the body or mind and improve your overall health and well-being. When you hear this, you may think: “So, like a green juice?” While green juices are definitely grouped in with functional beverages, it goes way beyond just that. Functional beverages include any drinks that contain fruits and/or vegetables, in addition to herbs, vitamins, minerals, probiotics, and more.

Functional beverages can be grouped into a couple of different categories, including:

- Dairy-based beverages

- Probiotic drinks

- Energy drinks

- Sports drinks

- Meal replacers

- Caffeinated beverages

- Fruit and vegetable beverages

That the trend towards more individuality and functional beverages is not a flash in the pan is shown by current studies from the market research sector.

8 reasons the functional beverage Industry is growing:

- Increased demand due to corona virus

- New ingredients

- Greater demand for plant based beverages

- More functional appliances available

- Desire for more healthy drink options

- Lager distribution channels

- Alternative stimulants

- Supplements that improve cognitive functions

Accordingly, the share of flavors in beverages is also growing, of course.

Global Beverage Flavoring Systems Market size was worth over USD 4 billion in 2018 and is projected to witness more than 5% CAGR from 2019 to 2025.

Growing health consciousness along with increasing prevalence of health issues such as diabetes, obesity and high blood pressure have resulted in consumers shifting to healthier beverages including sugar-free drinks, fruit juices, sports drinks, and functional drinks. Growing consumer consciousness and rising disposable coupled with a rapid increase in population will drive the business expansion. Further increased consumer spending for clean-label and organic products supported by favorable labeling norms and government initiatives to promote organic fruits production will foster the industry share.

Rapid growth in consumption of beverages with low sugars and less artificial ingredients with functionality including hydration, high in nutrients, better immune support and digestive wellness will drive the beverage flavoring systems market. Increasing sports activities and daily yoga regime will surge the demand for fruit juice and healthy drinks. Further innovations & launches in the ready-to-drink segment is positively influencing product penetration.

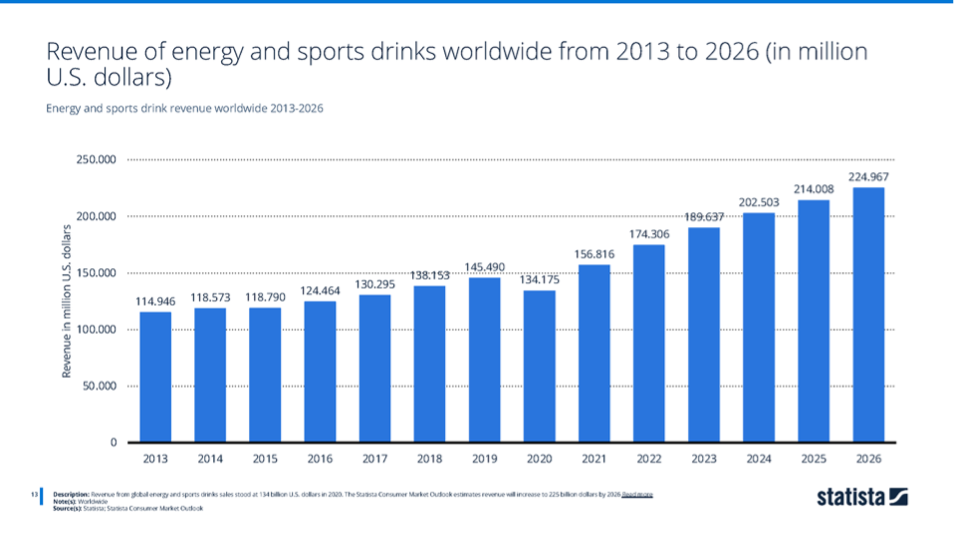

In addition the market for sports and energy drinks is growing rapidly.Statista forecast a turnover of 225 van $ until 2026, which means a doubling since 2013.

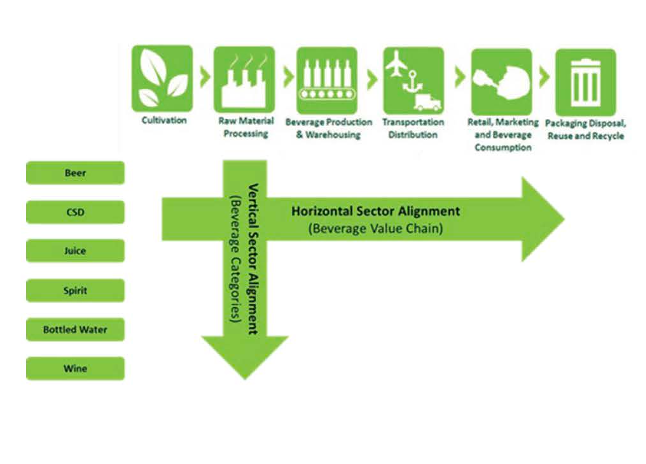

B. Challenges due to changing market demands

B.1 Problem of the bottlers and dealers

All this trends increase the product portfolio and reduce the lot sizes of the batches.

More and more beverage line manufacturers and bottlers are addressing the question: „Can very small batches down to batch size 1 be economically realized in a bottling line?“ This question has not been answered to this day. On the contrary. As the product range becomes ever larger and the batch sizes smaller, the bottlers‘ efficiency and plant utilization continue to plummet. The bottlers invested in the past millions of dollar in filling lines which produce big volumes in shorter times but the market trend is changing completely.

Bottlers who want to participate in product growth run the risk of spending more time cleaning and converting than bottling. There are analyses that show that it is not uncommon for pure filling time to account for only 45% of the available time when the product portfolio is diverse. At the same time, the consumption of resources such as water and chemicals is growing rapidly. It is not uncommon for a rinsing process of a filling line to require 6,000 litres of water. There are also flavours that are so penetrating that all cleaning processes are insufficient and even the seals have to be replaced.

The rapidly growing number of beverage products is not only a challenge for bottlers, but also for retailers. No matter whether e-commerce dealer, wholesaler, delivery service, beverage market or supermarket. Storage space is scarce and expensive and the logistics costs are enormous.

The customer promise to deliver a large selection in ever shorter time escalates the issue enormously.

B. 2 Circular economy in the beverage industry

Moreover, the circular economy for beverages is anything but sustainable. While drinks in glass bottles, for example, generate added value for the consumer, the return of empty bottles to the bottling plant is an ecological disaster.

The situation for the circular economy is exacerbated by the increasing individualisation of beverage bottles by bottlers. Whereas in the past a standard glass bottle from the GDB was used by all mineral water producers in Germany and could be returned to every well, an individual bottle must be returned to the respective bottler.

The bottlers hope that this marketing measure will attract more attention to their product on the shelves and ensure that there are enough empties during bottleneck periods.

B.3 Summary of the main problems of the worldwide beverage market

- The current market is unable to meet the growing demand for small batchproductions, limiting access to many potential new producers

- Current production models do not meet the needs for flexibility, growth and perfect repeatability that favor the development of a successful brand

- Internationalization costs are only sustainable for established brands with significant sales volumes

- Distribution and transport both have high environmental impact and products are perishable

C. These Challenges need disruptive solutions

C.1 How can this problems be solved?

If one is aware of the previously mentioned problems in the entire logistics chain, the time is ripe for a real disruption in the beverage industry.

KTW Technology has dedicated itself to precisely these issues.

What does a near-ideal solution look like?

We believe that there has to be a solution for the bottlers and a solution for the retailers.

The bottler must be put in a position to follow the market trend without having to accept any loss of efficiency and to operate sustainably.

The retailer must be relieved of logistics costs and largely fulfil the customer’s desire for individualization.

C.2 KTW´s solutions to disruptive the beverage industry

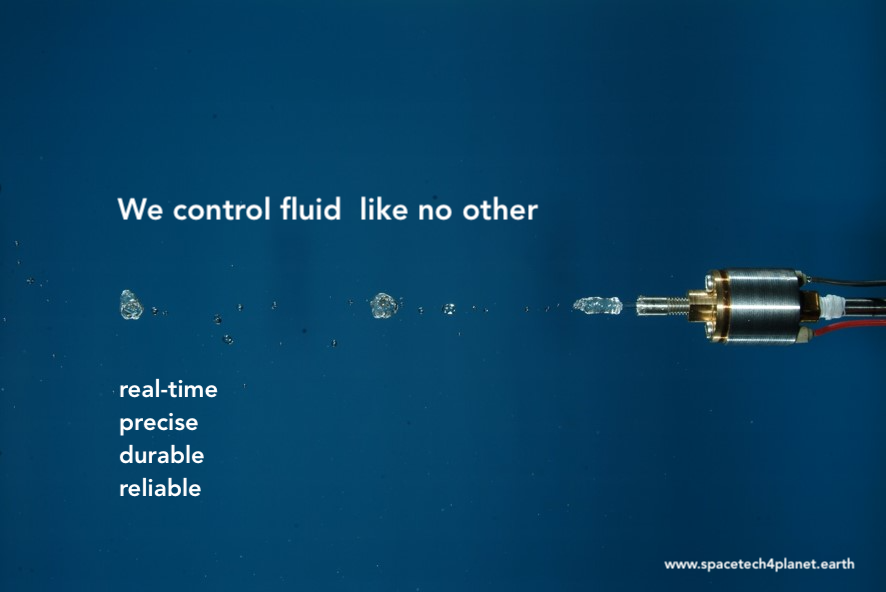

The KTW team uses space technology to develop efficient and sustainable solutions for industry. In addition to its products to promote the energy turnaround ( hydrogen and energy saving ), KTW has developed solutions for both, beverage bottlers and beverage dealers/retailers.

C.2.1 Disruptive Solution for the filling industry

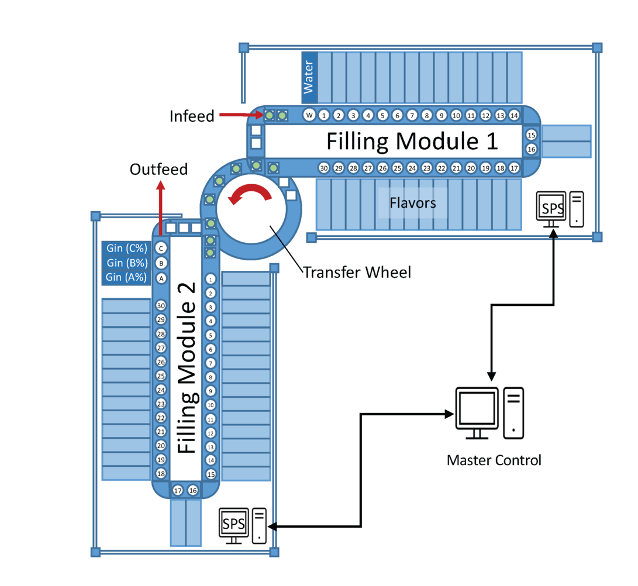

Here, bottlers are enabled to eliminate flavours and additives from the main filling process and to dose them separately before or after the main filling process using a unique and retrofittable technology, the High Speed Pression Dosing system.

The system’s high valve cycle speed (up to 35hz) means it is able to administer up to 2,000 doses a minute per valve or 120,000 doses per hour. At the same time, it can deliver variable dosages from 0.3ml to several liters and has a repeat accuracy equal to or above 98%, depending on size. In addition, the KTW High-Speed Precision Dosing System documents how much medium is delivered to ensure repetition accuracy.

This revolutanary change in the filling process enables the bottler to participate in small batch product growth without loss of efficiency. He has fewer cleaning processes, no flavour carry-over and a high degree of flexibility and less Capital Expenditures. The solution meets the sustainability aspect through less energy, water and chemical consumption. The system is retrofittable in every existing filling line!

This flexibility and economically filling of small lot sizes is known in the Beverage industry as „Bottling on Demand“ or „Filling on Demand„.

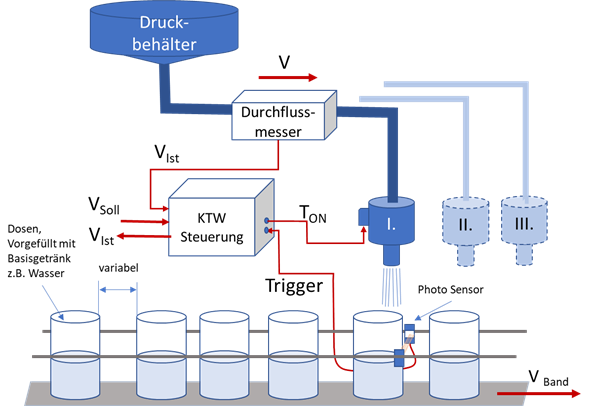

How does Pre- and Post-Dosing Work?

Pre- and post-dosing is different from conventional beverage mixing methods. Here, the flavor medium is added into a moving open container before or after it has been filled with a base medium. Mixing happens during transport.

This makes creating different flavors from the same beverage base much easier. The only part of the production line that needs modification is the one responsible for administering the flavoring. Yet, to be viable, a pre- or post-dosing system needs a high level of precision so that it can accurately implement recipes. In addition, it needs to be able to accommodate certain volumes to make sense economically.

In the KTW High-Speed Precision Dosing System, the dosing medium is supplied in special pressure vessels. Both the container pressure and valve opening times define the dosing quantity, which can either be initiated via sensor signal or external control impulses. The system is able to deliver precise quantities at a high rate and can also document the delivered doses to validate repetition accuracy. In short, it has all the features needed for modern food and beverage manufacturers to deliver what the market demands.

Operating Principle

- Dosing of the mediumthrough the opening of the moving container after filling with base medium (optionally before filling).

- Provision of the dosing medium in special pressure vessels

- Valve opening time and container pressure define the dosing quantity

- Dosing possible with linear and radial movement

- Initiation of dosing by sensor recognition or external control impulses

- Flow measurement for documentation of the dosing result and validation of the repeat accuracy possible

- Scaling of the dosing quantity by extending the valve opening times and using several dosing valves

The technical skills address the following tasks in the production/filling of beverages or liquid foods:

- Dosage of sensitive recipe components:

Components such as probiotics (e.g. kombucha), allergenic substances (e.g. nuts), product-changing enzymes (e.g. lactase in the production of lactose-free milk), or substances that are difficult to clean (e.g. energy flavoring) can be kept out of the process and filling equipment. This minimizes the cleaning timesrequired, eliminates the risk of carryover into downstream products, and removes existing restrictions on the use of equipment/machines (e.g. „once energy, always energy“ or „may contain traces of nuts“).

- Dosage of sensitive formulation ingredients:

Selected components (e.g. vitamins, flavors, essential oils) can be protected from negative influences in the manufacturing process (e.g. heat treatment or wort boiling in beer brewing) and thus product quality can be increased

- Volume-precise dosing of small quantities:

Direct dosing into the container allows the quantity of a component contained in the container to be verified (e.g. Vitam D3 / Vitam C additions), documented and guaranteed. Formulation reliability in the container is improved. The high demands on homogenization/mixing of the batch, especially in case of strongly deviating volume ratios, are avoided. Process times are reduced.

- Dosage of product-differentiating formulation ingredients:

Direct dosing of low-volume formulation components that differentiate between specific characteristics/flavors of a product (e.g. flavors in flavored water, near-water beverages, craft beer, carbonated soft drinks) minimizes the product changeover time between the individual characteristics within the product group. The base product is produced conventionally and filled into the container, while the differentiating component is dosed into the container (pre- or post-) separately and with exact volume. By switching on or off one or more direct dosing units, it is possible to switch between products and/or formulations. Any cleaning times required to avoid flavor carryover can be avoided.

C.2.2 Disruptive Solution for the retailers / dealers:

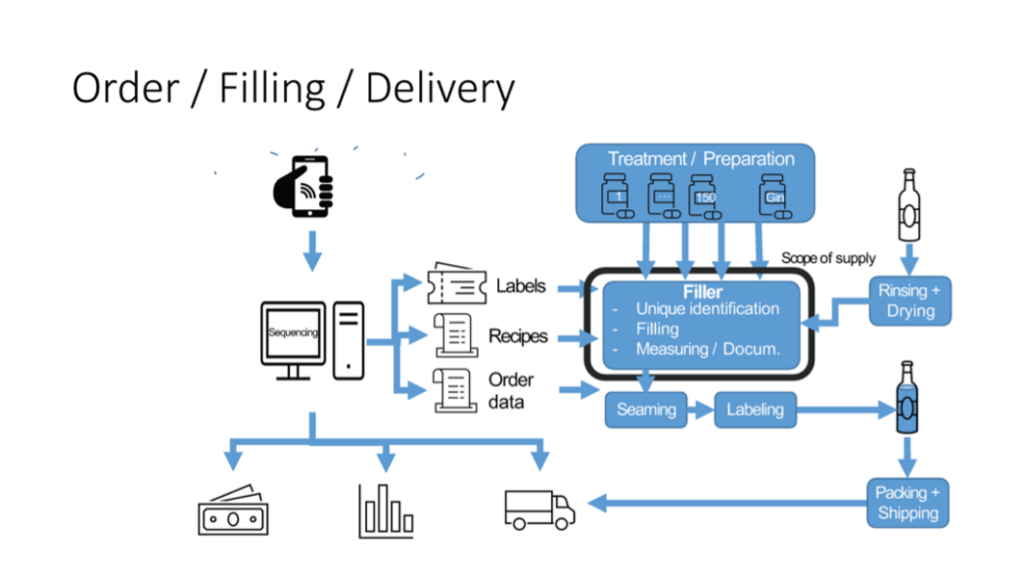

However, KTW’s strategy envisages a much more far-reaching change in the bottling of beverages. A real disruption is taking place in which an entire market is being replaced or „smashed“ by a rapidly growing innovation. For this reason, KTW has developed a concept with a customer in which the entire logistics process and the complex warehousing up to and at the dealer/retailer are greatly simplified for certain types of beverages.

Small and flexible dosing lines are operated, for example, in the warehouses of the dealers themselves or by the KTW team. Here, alcoholic and non-alcoholic beverages with a variety of flavours and additives can be filled homogeneously and delivered to the customer, who composes his product via mobile app, in the shortest possible time. The current project provides for the dosing of 150 flavours in alcohol for an online dealer.

The solution enables online dealers and delivery serviceto have the following points of differentiation:

- Complete process automatization

- Minimum batch sizes– beginning from one bottle principle

- Worldwide repeatable by production scaling

- Reduced Carbon Footprint by local manufacturing

- Flexibility and speed to customer

- Own beverage brands

The advantages for the dealers and the circular economy are enormous. Besides the aspect that they can build their own brand with very individual beverages, they generate a competitive advantage and a drastic cost reduction in logistics. In addition, empties for these beverages no longer have to be returned the whole logistic process to the bottler for refilling, which nature and the climate will thank us for.

C.3. Equipment as a Service

In further expansion stages, KTW Technology flexibilizes its model to the extent that the dealer can choose between in-house operation, purchase as “Equipment as a service” or third-party operation by KTW personnel.

Equipment as a Service can offer significant benefits to the customer and the equipment manufacturer. Instead of making a large investment, the customer pays for dosing and other services under a long-term service contract.

D. Final Statement

KTW’s innovations are solutions for more efficiency and sustainability for bottlers and distributors who (want to) produce and sell alcoholic and non-alcoholic beverages with additives.In addition this products are growing very strongly according to market research. Inefficient production processes and supply chains are eliminated. The positive impact on emission avoidance and resource wastage is huge.

If you are interested to learn more about this real disruption in the beverage industry, please contact us under info@ktwtechnology.de