Patent EP 3723933 erteilt

Unter der Patentnummer EP 3723933 wurde uns das Europäische Patent „ Hochvakuumkammer, und Verfahren zum Betrieben einer Hochvakuumkammer für die thermische Bearbeitung eines Werkstücks mittels

A highly durable and adaptable liquid-to-liquid dosing appliance for a multitude of industrial applications. Pay special attention to our flagship, food-grade pre- and post-dosing system that is perfect for food and beverage manufacturers, healthcare and pharmaceuticals, cosmetics and logistics, and industrial fluids.

The product variance in the food industry is growing. Especially in the case of beverages and liquid foods, more and more recipes require the addition of small quantities of flavourings or additives. The risk of flavour carry-over in filling plants is increasing. Filling lines have to be thoroughly cleaned more and more frequently, at the latest when the product is changed. The plant efficiency decreases!

"Post-dosage effectively prevents contamination of the filling line".

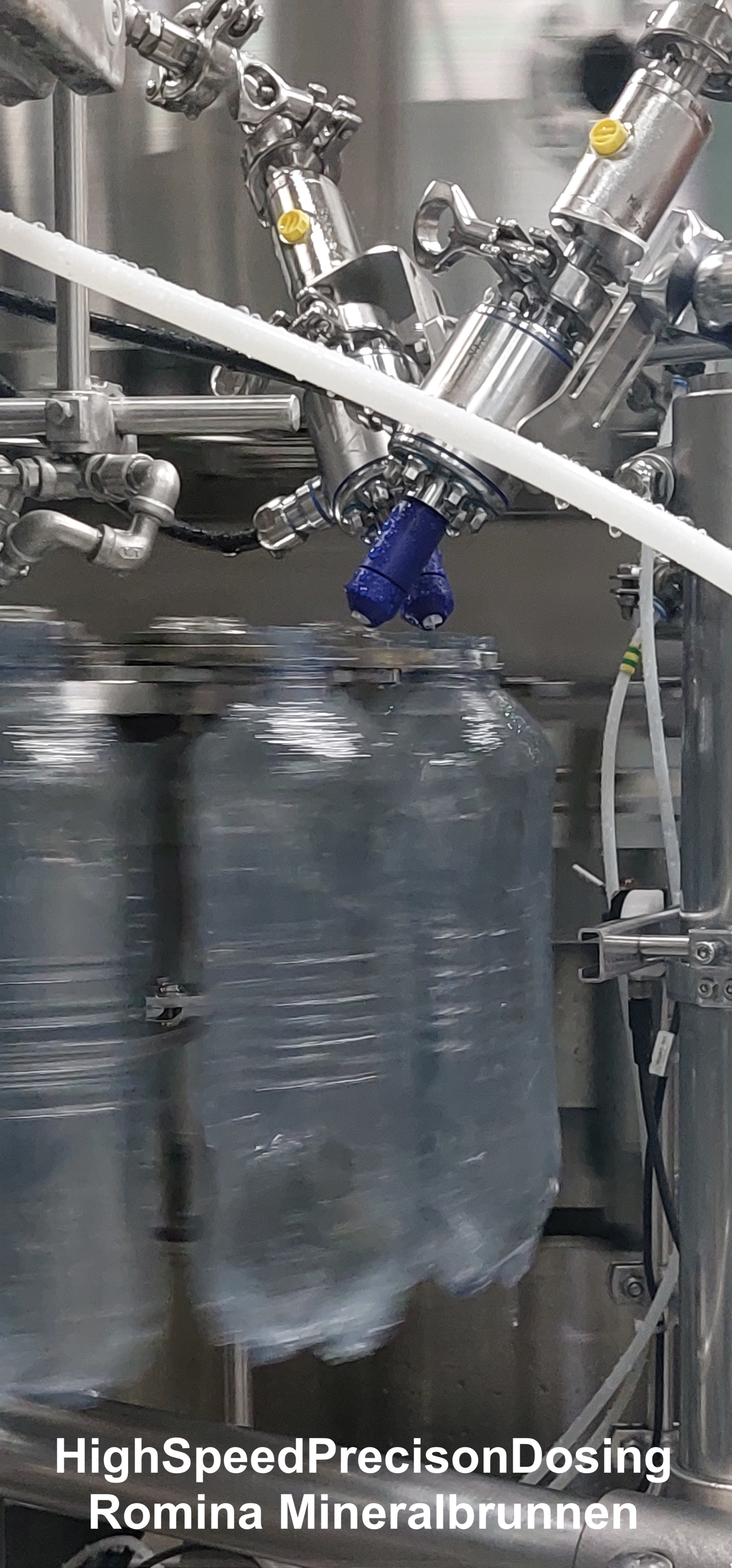

The solution is simple: the filling line fills the base drink. Then the flavourings and additives are post-dosed outside the filler. The media are mixed during transport. Up to now, this form of filling has been hampered by the high speed and accuracy requirements. A limitation that is eliminated by the innovative KTW High-speedPrecisionDosing System .

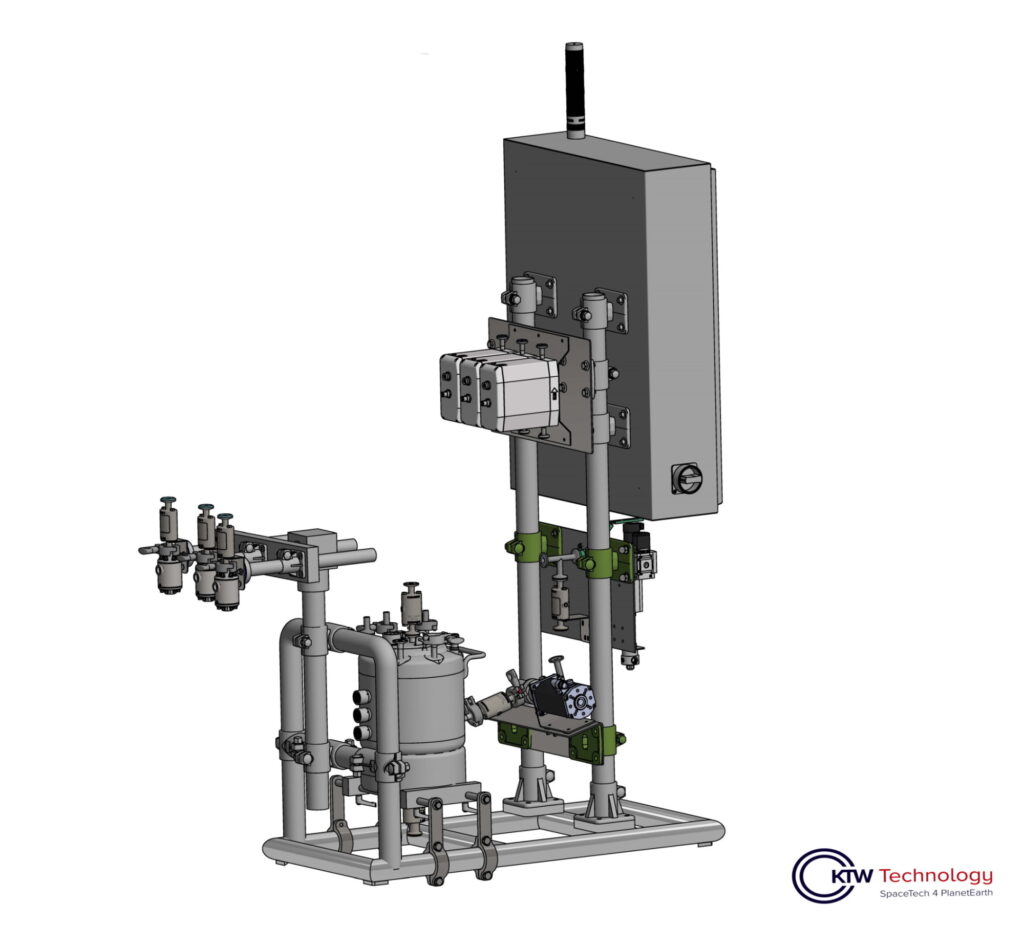

Our fully automated system is perfect for any purpose that requires fast dosing of precise amounts of liquid media into other fluids, including into moving containers. Available as both a modular, standalone version as well as an integrated variety, it easily adapts to most working environments. While the system is suitable for many purposes, the star of the show is our food-grade edition for beverage production.

With our fast and precise pre- and post-dosing system, we are aiming to address the challenges that food and beverage makers have found themselves facing in recent years. In many places, consumer demand for more flavor variety have necessitated a shift from mass production to smaller batches, something a lot of facilities are not prepared for.

Many operations were originally aimed at large volumes with little variation. Transfering to smaller batches and more flavors requires time-intensive cleaning and modifying the equipment to avoid flavor carryover. The result is an increase in idle time, lower production volume, and an overall loss of efficiency. Plus, working with inferior valve technology unsuited for the demands leads to high maintance, low switching cycles, and frequent need for maintenance.

Especially facilities with few production lines have been faced with the question whether to make possibly substantial investments into new equipment, extensions, or entirely new lines. For those, and everyone else, the KTW High-Speed Precision Dosing System offers a cost effective alternative.

Based on KTW Smart Valve Technology the pre- and post-dosing system boasts exceptional precision and speed. Its modular makeup allows it to integrate into almost any existing environment and production line. Once in place, the system enables beverage producers to ramp up production variety with minimal investment, making facilities much more flexible to meet changing consumer tastes.

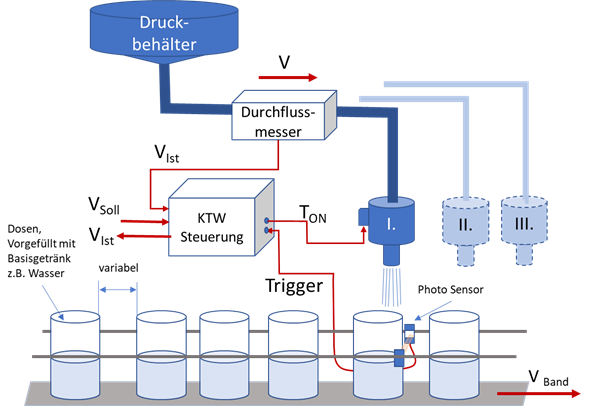

Pre- and post-dosing is different from conventional beverage mixing methods. Here, the flavor medium is added into a moving open container before or after it has been filled with a base medium. Mixing happens during transport.

This makes creating different flavors from the same beverage base much easier. The only part of the production line that needs modification is the one responsible for administering the flavoring. Yet, to be viable, a pre- or post-dosing system needs a high level of precision so that it can accurately implement recipes. In addition, it needs to be able to accommodate certain volumes to make sense economically.

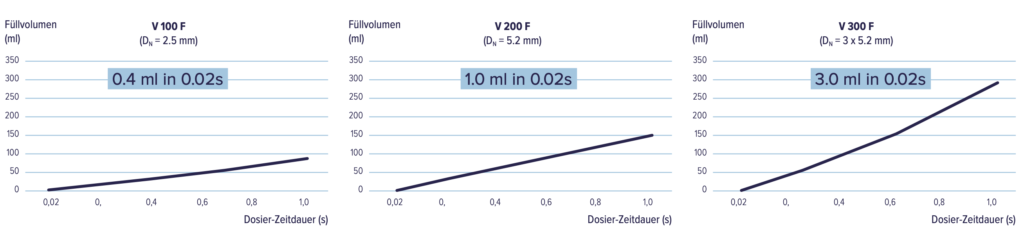

In the KTW High-Speed Precision Dosing System, the dosing medium is supplied in special pressure vessels. Both the container pressure and valve opening times define the dosing quantity, which can either be initiated via sensor signal or external control impulses. The system is able to deliver precise quantities at a high rate and can also document the delivered doses to validate repetition accuracy. In short, it has all the features needed for modern food and beverage manufacturers to deliver what the market demands.

The system's high valve cycle speed (up to 35hz) means it is able to administer up to 2,000 doses a minute per valve or 120,000 doses per hour. At the same time, it can deliver variable dosages from 0.3ml to several liters and has a repeat accuracy equal to or above 98%, depending on size. In addition, the KTW High-Speed Precision Dosing System documents how much medium is delivered to ensure repetition accuracy.

Pre- and post-dosing reduces or eliminates the need for complex mixing processes and allows for the simple adaptation of recipes. Cleaning is limited to the dosing module whose mobility makes it easy to switch out, thus rendering fulfillment of small orders and batch sizes much more efficient. The system can also accommodate flexible filling strategies (meaning different valves administering varying amounts) per dosing, for example, to avoid splashing.

It’s possible to use up to three valves per valve station, each working independently. Dosing is possible for linear and radial movement and works with almost all open containers (bottles, cans, beakers, canisters, etc.). The beverage dosing system also makes it simple to scale up by extending valve opening times and using several dosing valves.

Using the KTW High-Speed Precision Dosing System reduces the need for cleaning the entire production line between and during individual filling jobs. It eliminates aroma carryover in mixing and filling machines, has a space-saving design, short setup times, and allows for quick changeover between flavors. This means greater flexibility in planning and less downtime, making the system an affordable solution to expand your product portfolio. In addition, it is temperature and rust resistant, comes with long durability (in excess of five billion cycles), and a low need for maintenance.

Pic: Design of the high speed precision dosing system for filling cans.

Important technical details of the stand-alone system:

All KTW High-speedPrecisionDosing Systems are based on the KTW SmartVale Technologie and benefit from the unique capabilities of this valve technology:

"The KTW High-Speed Precision Dosing System forms the basis for a completely new and flexible form of beverage filling without batch size limits."

The KTW High-Speed Precision Dosing System is suitable for a wide range of functional drinks and beverages, including but not limited to:

In detail, the technical skills address the following tasks in the production/filling of beverages or liquid foods:

The pre- and post-dosing system is available in different configurations and either as a standalone system or as an extension for your existing production line or facility.

In particular, we offer:

The dosing technology is also available as:

It should also be noted that the above-mentioned restrictions on the dosing of small or low volumes only exist in relation to the application, due to the dosing in moving containers. In principle, this technology can also be used for the repeatable dosing of larger quantities/volumes, but this requires a dwell time of the container under the dosing unit that is adapted to the required dosing volume.

The application of dosing technology in a non-food sector is also possible and makes sense, insofar as comparable filling requirements exist here. Beispielmärkte sind Pharma, Chemie und Industrieflüssigkeiten.

Unter der Patentnummer EP 3723933 wurde uns das Europäische Patent „ Hochvakuumkammer, und Verfahren zum Betrieben einer Hochvakuumkammer für die thermische Bearbeitung eines Werkstücks mittels

Please read our Newsletter : Like other industries the beverage industry is going to miss its greenhouse emission reduction targets 2030 and 2050 and is

We'd love to support you to succeed in your industry. Request a free call back, and let's talk about how we can tackle the challenges which your industry faces.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.