In times of energy saving and sustainability, pneumatics is coming under increasing pressure. Many applications are based on uneconomical generation of compressed air. The efficiency of generating mechanical compressed air energy from electricity is just 5%. According to an EU study, 80 out of 100 companies produce up to 100% more compressed air than they consume. Energy costs are rising! The energy balance of the companies gets more and more into the focus. Companies that have recognized this are partly using modern and economical compressors.

Our approach is different and more effective – and cheaper!

Based on our SmartValve technology we dramatically reduce the pneumatics or replace them in an efficient and energy-saving way! On the one hand, we completely replace pneumatics with our real-time solenoid valve technology. An example are pneumatic functions in machines. Machines are becoming faster and faster and more and more energy-saving – pneumatics is often overwhelmed here by the performance and efficiency. Continue reading here: https://ktwtechnology.de/en/business-units/smartvalve-technologie/

70% of all compressed air applications are used for drying, cleaning, controlling and blowing off – and often in continuous operation! Our AirFlowSaver reduces the compressed air where it exits – namely at the product, and this between 50 and 95%! This is where the optimization has to take place. And this optimized quantity tells your compressed air system which compressor makes sense and not vice versa.

Continue reading here: https://ktwtechnology.de/en/products/airflow-saver/

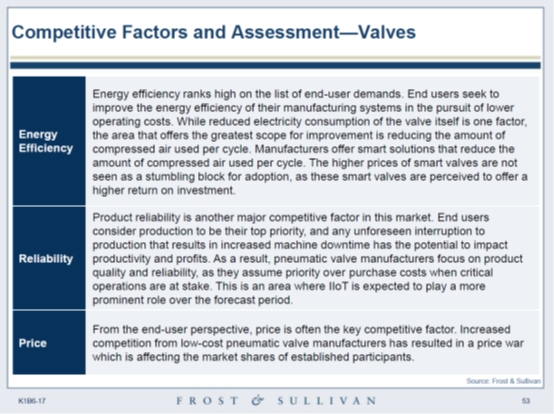

A market study by Frost & Sullivan puts it in a nutshell. The challenges for pneumatic valves lie in greater energy efficiency and reliability.