In the history of the development of Titan Matrix Composites (TMC) there have been two successful implementations of this technology.

The first implementation took place in 2002 in the engines of the TOYOTA Formula 1 Racing Cars.

Stud bolts, piston pins or connecting rods are a few samples.

For details see the following report in the ATZ journal Novmber 2007:

Engine parts made of TMC were a reason why TOYOTA engines convinced with one of the staunchest engines in Formula 1 history. TOYOTA used TMC from 2002 until 2006.

In following year FIA changed the regulations and banned all Composites materials.

Technical Director at TOYOTA Formula 1 was Norbert Kreyer. Klaus Weber is the inventor and has introduced TMC at TOYOTA as an engineer of the German Aerospace Center. Both are today members of our Management Team.

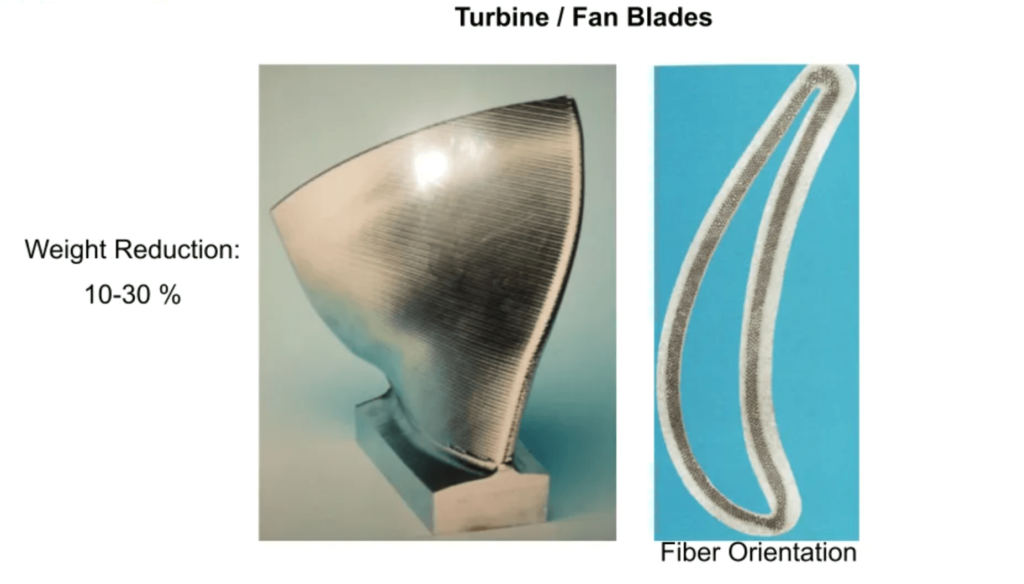

In 2013 Klaus Weber started a Project to implement this Technology in the Russian Aviation ( www.viam.ru). TMC is now successful implemented there. Typical applications are Turbine / Fan Blades (weight less 30%), Impeller Blade Wheel (weight less 30%)