KTW NovoDoser

The Ultimate Solution for Preserving, Pressurizing and Freezing Your Products

Discover the ideal solution to ensure the safety and stability of your products during transport after filling, while improving their shelf-life and appearance. Our LN2 dosing technology has been successfully used in 1000+ applications by hundreds of customers worldwide.

Brand-new packaging concept

The food and beverage industry faces challenges in maintaining product quality and freshness during transportation and storage. Oxidation is a major issue that can lead to spoilage and reduced shelf-life. To combat this, headspace inerting is used to displace oxygen inside the package with an inert gas (nitrogen).

Traditional methods of dosing inert gas are mostly slow, inaccurate, energy-intensive, and prone to errors. This results in inconsistent and inadequate filling, which can lead to quality variations, spoiled products, and consequently lost revenue.

In this context, dosing liquid nitrogen (LN2) has proven to be an ideal solution, especially for products that are sensitive to oxidation and/or contain thin-walled packaging material.

"Our dosing technology enables exceptional accuracy and control over the dosing process. It ensures that you can achieve the desired preservation, pressure equalization, or freezing effect, regardless of how complex your application is."

Why use LN2 Dosing System?

Container Pressurization

Liquid Nitrogen Dosing enhances product packaging quality, provides significant cost savings. Through container pressurization and subsequent rigidity improvements, packaging material can be reduced. Thus, allowing cost reductions in packaging material and ecological carbon footprint.

- Prevent deformation and damage during transportation of containers

- Improve labeling from better container rigidity

- Improve palletizing in factory warehouse

- Preserve the bottle/can shape in the supermarket and allow product sales via vending machines

- Compensate for atmospheric pressure differences (eg. mountain – sea level)

Why use LN2 Dosing System?

Inerting

LN2 dosing is the most effective process for inerting food & beverage containers to achieve desired oxygen exclusion. Delicate products filled into bottles/cans/jars should have very little contact with oxygen for the following reasons:

- Prevention of product oxidation

- Avoiding the need to add oxidation inhibitors

- Avoiding collapse of the package (paneling)

- Preserving taste, color, and freshness of the product

- Increasing the shelf life of the product

How does it work?

Novo Doser

LN2 is supplied to the doser by a vacuum-insulated pipe and flows into the dosing head. Sensor will detect the container and send pulses to the controller. Controller will command the dosing head to dispense the required amount of LN2 into the container. LN2 droplets quickly evaporate and expand 700X into gaseous N2 equivalent, filling the container headspace with inert N2 gas at the desired pressure.

Key Features

Frost-free Nozzle

Self-generating GN2 for dosing head blanketing

Consistent Container Pressure

Deliver accurate dosing ± 1%

Lowest LN2 Consumption

Discrete dosing, for speed up to 2000* containers per minute

Lowest LN2 Losses

Proprietary vacuum insulation with lowest heat leak, faster capital payback

Minimized Product Splash

Lowest dose pressure in its class, 0,02 bar

Lowest System Downtime

Sensors & Electrical cables are IP 65 rated and 316L material grade of construction for main system

Highest Hygiene Wash Down Design

All external surface construction is in round shape, surfaces are sloped for self-drain ability and easy wash-down

Lowest Maintenance

Ultra-long life cycle dosing valve > 60 million

Ease of Installation

Compact size enables ease of installation in limited spaces

Applications Flexibility

Compatible with soft-dose and micro-dose technology for hot fill, powder, and granular applications

Multi-lingual HMI

German, English, Spanish, etc

5 Years Vacuum Warranty

Lowest cost of ownership

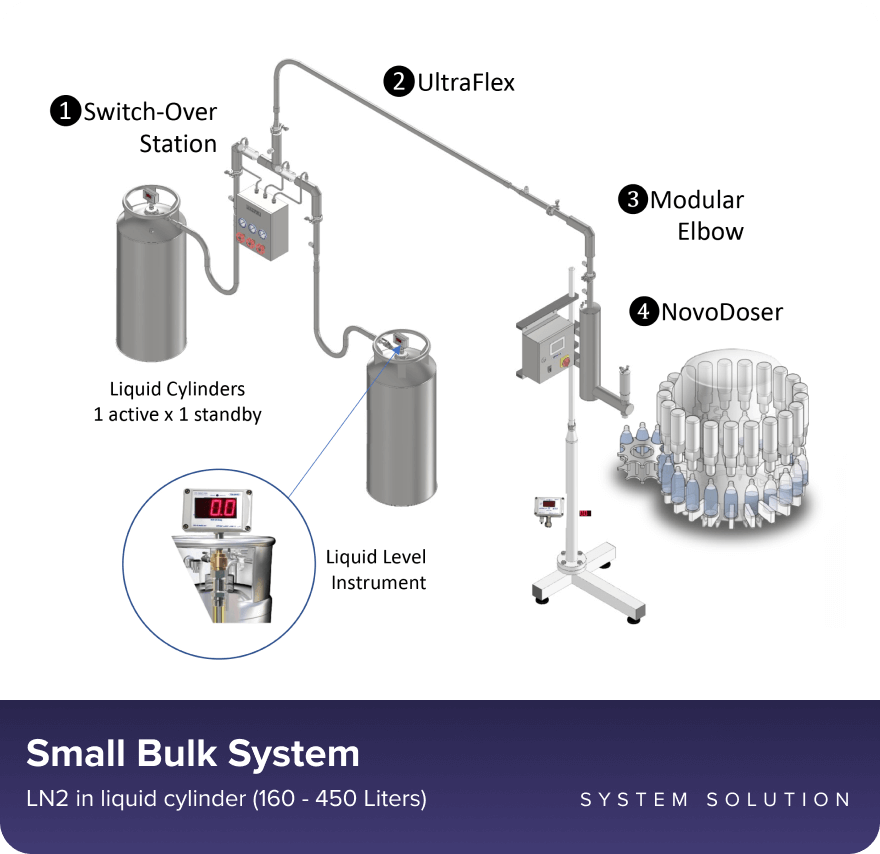

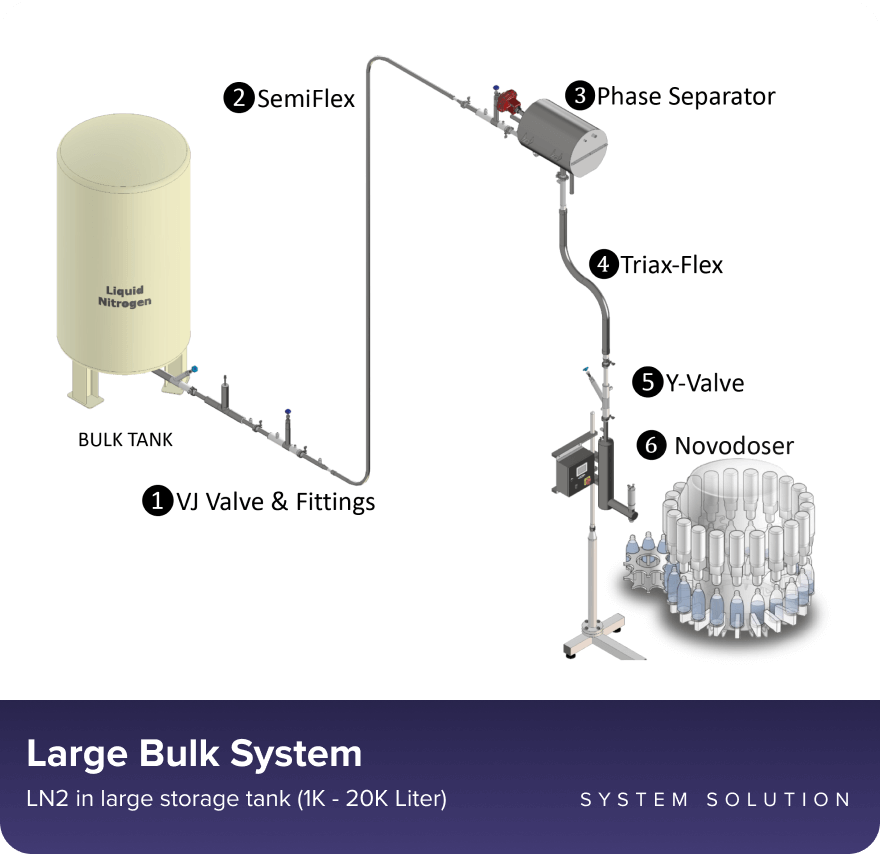

System Solutions

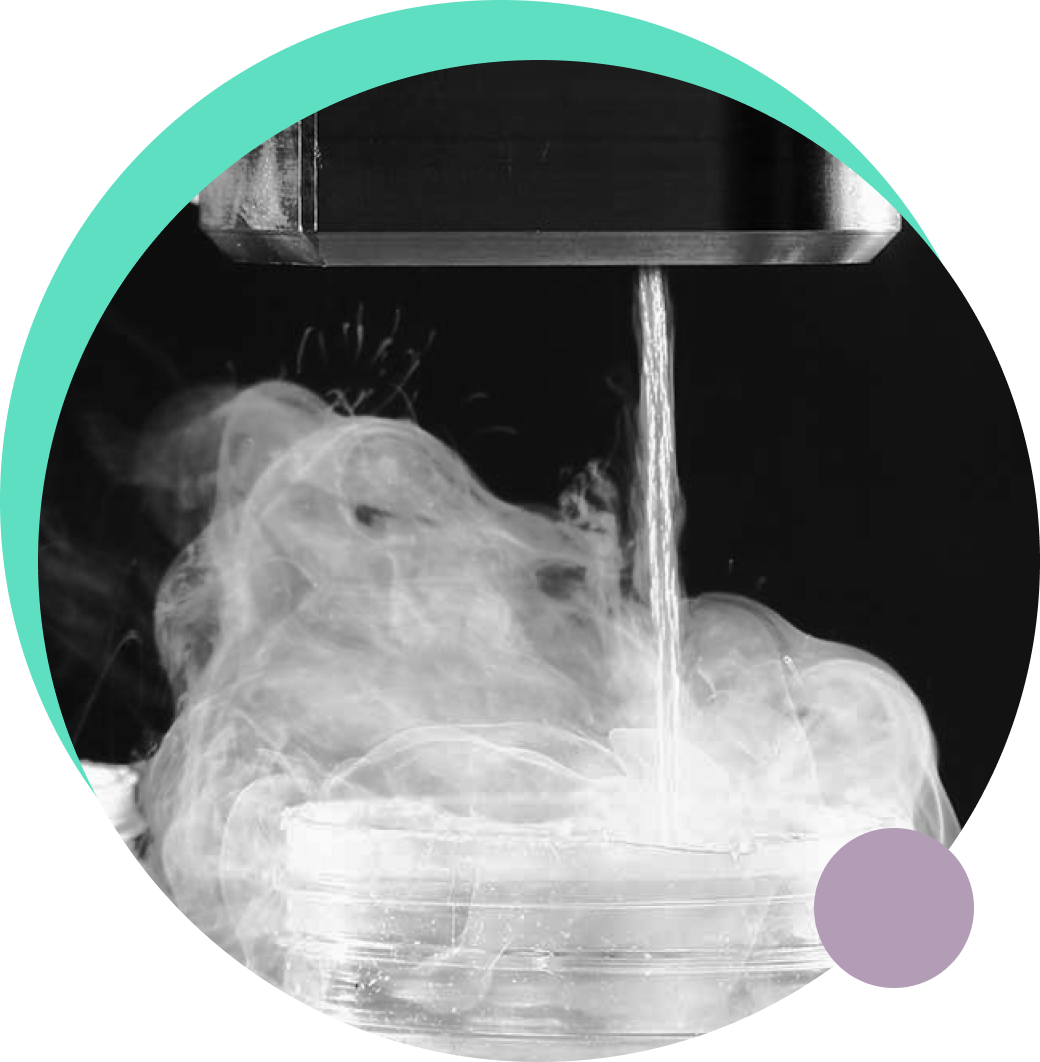

An example of the application of liquid nitrogen

Nitro Beer

Nitro beer, the avant-garde of brew innovation, represents a new generation of craft beer, delivering a velvety smooth texture and heightened flavor experience with its nitrogen-infused effervescence.

Trusted by

used worldwide in 1,000++ installations with 100++ customers

Technical Specifications

Do you have questions about our KTW NovoDoser?

Leave us your name and telephone number. We will get back to you as soon as possible.