How we make the can industry sustainable!

The inefficient and expensive Compressed Air is used in every manufacturing industry worldwide. To a large extent, the can manufacturing industry consumes compressed air, for

Reduce compressed air consumption in your enterprise. Use less, achieve more, eliminate waste, and increase performance with a cost-efficient and customizable system that adapts to your needs and environment.

Compressed air is an expensive energy source. Rising energy costs and the social focus on CO2-emissions and climate protection are aimed in particular at identifying and reducing energy wastage.

"It's time to rethink the use of compressed air!"

The first step in increasing the efficiency of compressed air systems is to optimise the applications. Only then is the optimisation of compressed air generation and distribution carried out. This is the only way to avoid oversizing the entire system.

KTW AirFlowSaver addresses the main issues of all compressed air applications. While an essential part of many processes, industrial compressed air is one of the most energy-intensive resources, costing up to ten times more than electricity. What’s even worse, a lot of it ends up wasted.

Energy losses in compressed air systems are dually bad for business. First, they waste money in the here and now. Secondly, an inefficient operation sets you up for difficulties in a future that is shaping up to be increasingly energy conscious and regulated due to efforts to curb greenhouse gas emissions and energy waste.

So far, most efforts have focused on savings on the production side in the form of more energy-efficient compressors and reducing leakage. KTW AirFlowSaver, on the other hand, deals with the other side of the coin: reducing consumption. By lessening the overall need for compressed air, you can potentially scale down the entire compressed air system of your operation.

"Nearly 70% of all industrial compressed air applications can become more efficient with the KTW AirFlowSaver !"

Our clients see reductions in the use of compressed air by at least half while benefiting from 15-20% higher impulse force. The increased energy efficiency often allows scaling down entire compressed air systems. It also means faster processing times, improved effectiveness, and reduced energy cost, making your entire operation more efficient and cost effective.

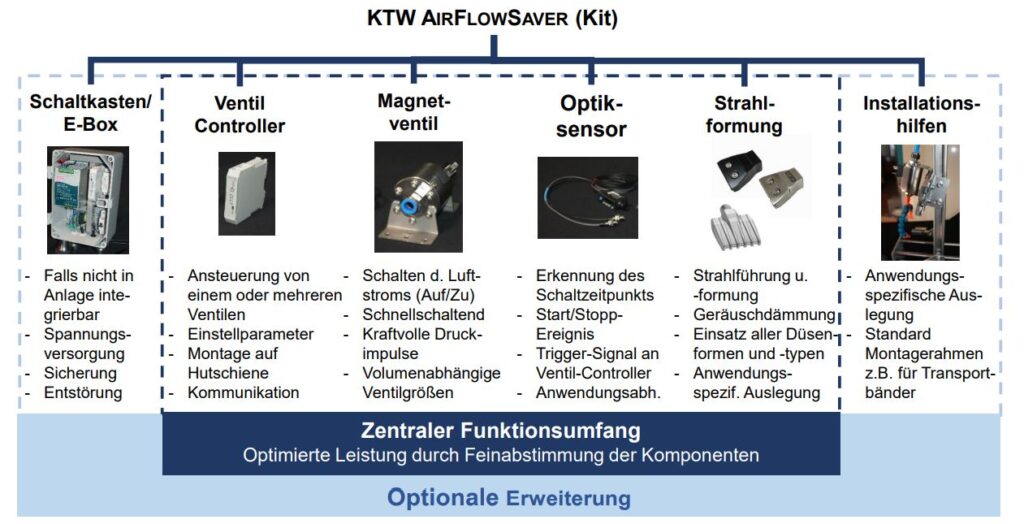

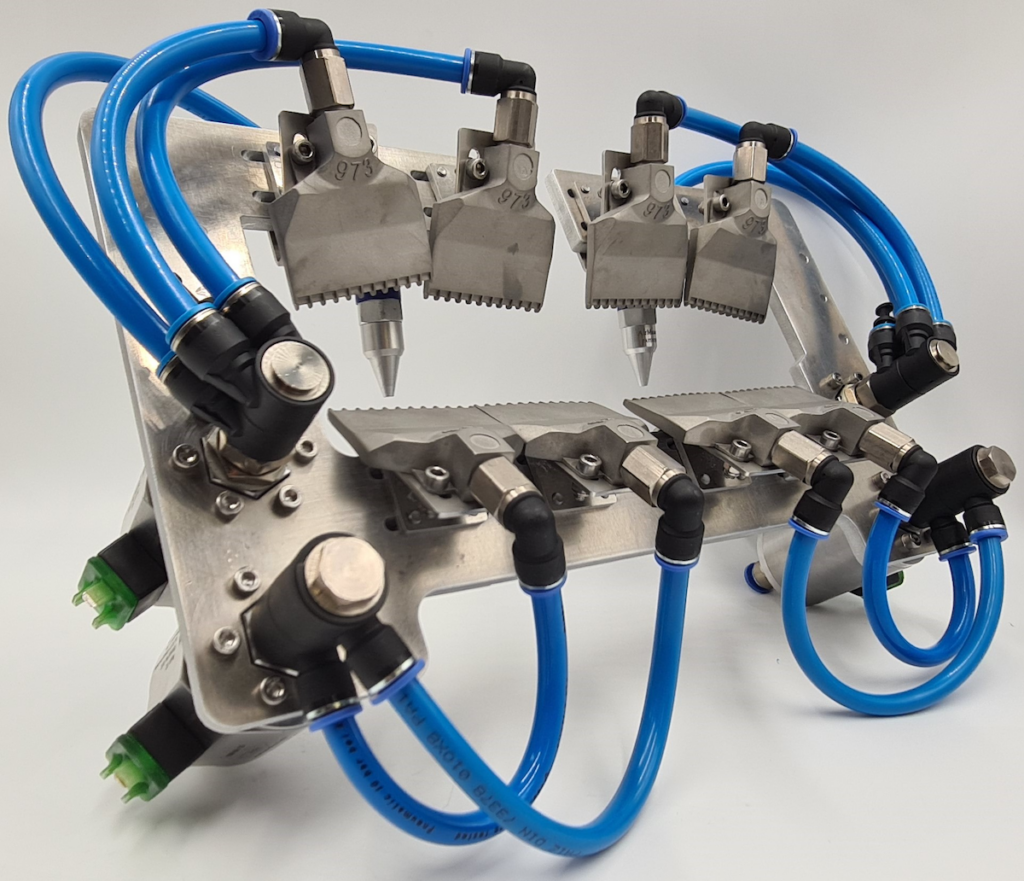

KTW AirFlowSaver is available in a wide range of configurations. You can customize the controller, valve, nozzle, sensor, as well as assembly and connector parts. As a consequence, it’s possible to pick the best components for the job, including existing equipment, and finetune each part to best fit your needs and process. At the same time, it makes it easy to upgrade and downgrade as needed.

Thanks to its modular makeup, the compressed air system integrates into any existing system or working environment. It is able to adapt to almost any industrial compressed air system, existing processes, and specific requirements. For example, KTW AirFlowSaver is available with pressure levels of 1-10 bars (higher levels on request). Some standard configurations for common compressed air applications (e.g. drying bottles) are available as well. Custom solutions can easily be created on demand. Additionally, you have the option to choose a rental option.

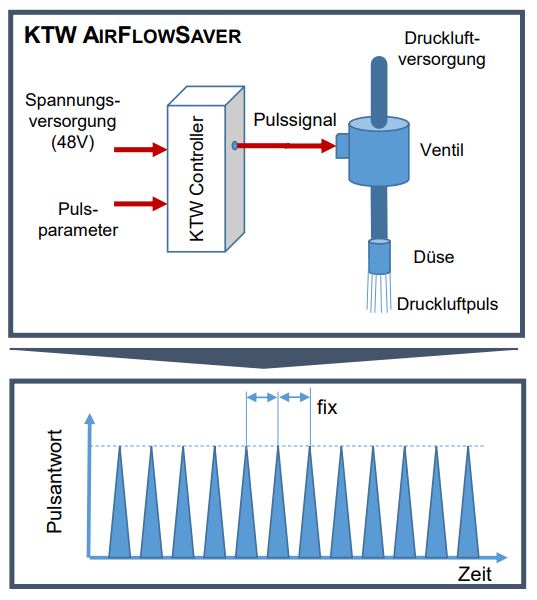

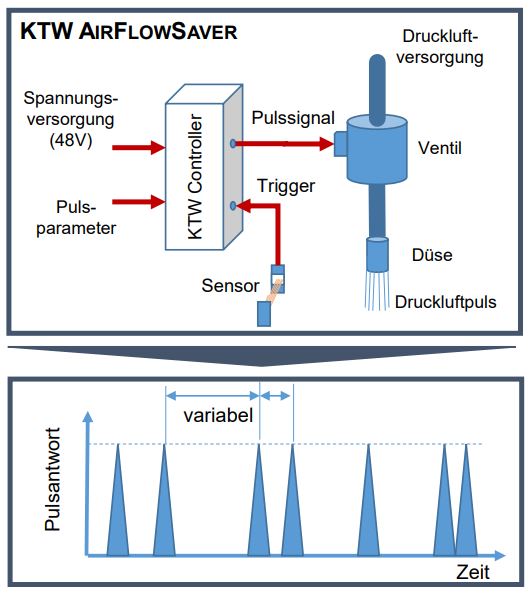

KTW AirFlowSaver can run in three different modes:

The controller is able to open and close the valve upon sensor impulse almost in real time. It has a reaction time of 1ms and a switching time of 1.5 to 2ms for a closed cycle.

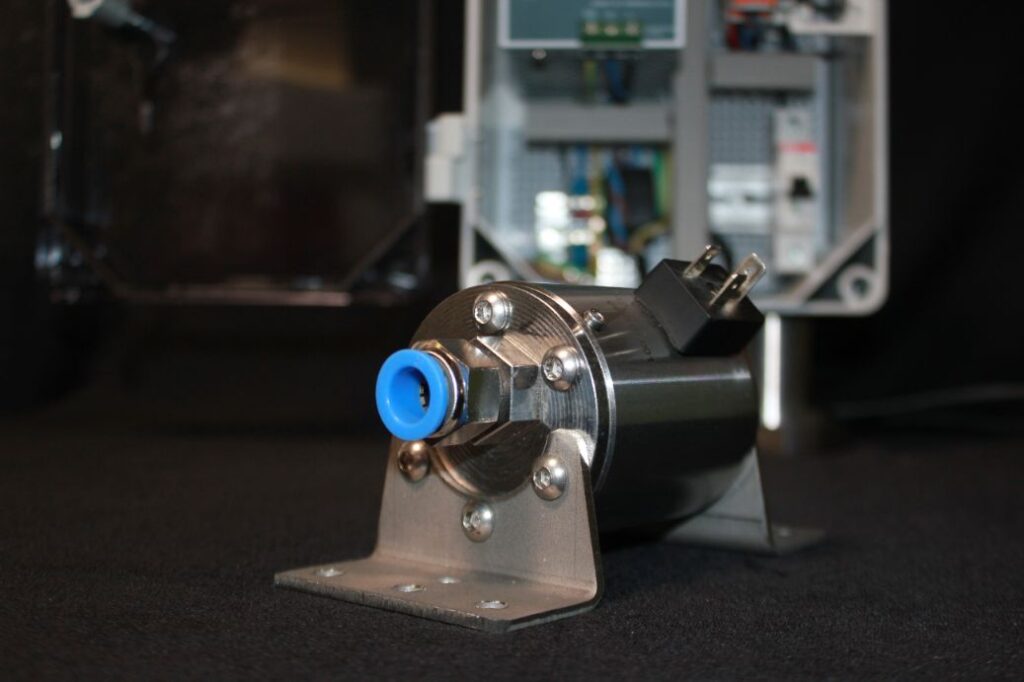

KTW Smart Valves last several billion cycles, are easy to maintain, and rarely need replacement. The result: less downtime and fewer replacement costs. Our clients typically see amortization of their investment in less than a year.

The KTW AirFlowSaver consists of function-oriented modules. For each of these modules, different technical solutions are available in a configuration kit. Thus the KTW AirFlowSaver can be adapted to almost all requirements and framework conditions. Standard configurations are also available, e.g. for blowing off and drying beverage packs, bottles and cans.

Pulsing increases the mechanical stress on conventional compressed air valves, which often fail after only a few million switching cycles and have to be replaced.

The KTW SmartValve Technologie allows several billion switching cycles without loss of functionality.

The KTW AirFlowSaver ensures that compressed air is only used when necessary. Thus, the sensor detects the event, e.g. the presence of an object, where the compressed air flow needs to be opened. Due to the direct connection of the sensor with the valve controller, the switching of the valve takes place without delay in almost real time.

The flow of compressed air is closed for the entire period in which the sensor does not report an event. Switching on and off, e.g. during interruptions, standstills and/or pause times, is not absolutely necessary. Another cause of wasted compressed air is thus also eliminated.

The switching speed of the valve is decisive for the pulse strength and the consumption of compressed air. With a reaction time of 1.0ms and a switching time of 1.5-2.0ms for a closed cycle), the KTW AirFlowSaver is a top performer among compressed air applications.

This enables very short yet powerful pulses with low air consumption - both with regular and event-controlled pulsing. These features also offer advantages for classic pneumatic applications.

KTW AirFlowSaver is suitable to reduce compressed air use in a number of different pneumatic applications and industrial equipment, including:

As a consequence, among others, the technology can benefit companies from the following industries:

Our customer Integrated Packaging Solutions supports the can industry with products, services and training that help customers produce more quality cans. Headquartered in Colorado, USA, IPS has built a global customer base that excels in innovation, quality and reliability.

In the video, Kalvis, Global Director Business Development explains which efficiency and savings successes are achieved with our valve technology in the "Bodymaker" and "Cupper".

The inefficient and expensive Compressed Air is used in every manufacturing industry worldwide. To a large extent, the can manufacturing industry consumes compressed air, for

Do you know the valves with the biggest impact ever? The SmartValve from KTW Technology GmbH ist standing for saving energy and emissions, reducing maintenance and down

Our customer Integrated Packaging Solutions supports the can-manufacturing industry by providing specialized products and can-making services. We are proud that they use our SmartValve technology to increase

Leave us your name and telephone number. We will get back to you as soon as possible.