Patent EP 3723933 erteilt

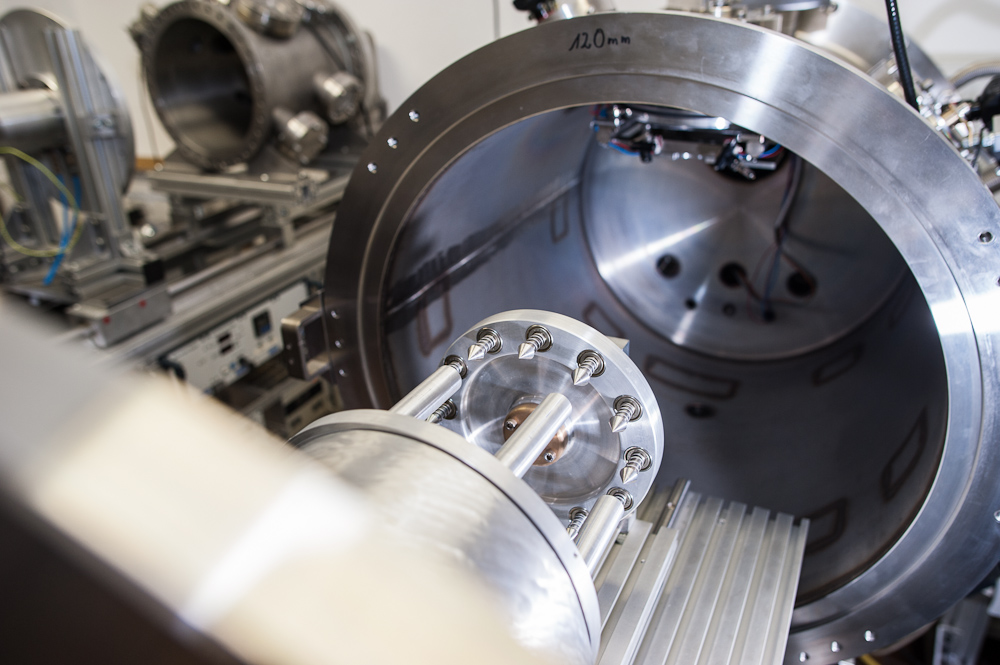

Unter der Patentnummer EP 3723933 wurde uns das Europäische Patent „ Hochvakuumkammer, und Verfahren zum Betrieben einer Hochvakuumkammer für die thermische Bearbeitung eines Werkstücks mittels

The combination of the advantages of welding under vacuum with the advantages of the laser beam as an energy source promises to meet the highest demands on the weld seam. The technical implementation alone involves the risk of high production and investment costs. Above all, the evacuation of the processing area necessary for vacuum welding places the highest demands on the system design in terms of energy supply and process efficiency.

The KTW vacuum laser welding system offers an innovative and unique solution. The modular concept allows the system design to be adapted in performance and economy to the specific requirements of the application. The separation of the laser source and the vacuum chamber increases the output per evacuation cycle and simultaneously minimises the required evacuation time. Capable handling technology enables parallel and sequential welding operations.

Quality in welding has a new name

tantalum, niobium

Mixed material compounds

Unter der Patentnummer EP 3723933 wurde uns das Europäische Patent „ Hochvakuumkammer, und Verfahren zum Betrieben einer Hochvakuumkammer für die thermische Bearbeitung eines Werkstücks mittels

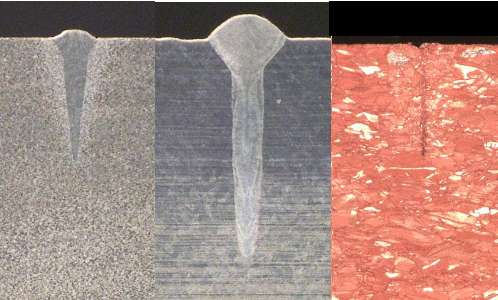

The quality of a leaser welding seam depends on in which pressure environment it happens. See in the video the difference between welding in vacuum

Das Branchenportal: „Home of Welding„, hat einen Bericht über unsere Innovation im Laserschweißen veröffentlicht. Hier der Bericht im BranchenportalDer Bericht stellt heraus wie unser Schweiß-System

We'd love to support you to succeed in your industry. Request a free call back, and let's talk about how we can tackle the challenges which your industry faces.